On August 28, 2023, BE Petrothai Group received a certificate of recognition from the Low Emission Support Scheme (LESS), a project supporting activities to reduce greenhouse gas emissions, by the Ministry of Natural Resources and Environment and Thailand Greenhouse Gas Management Organization (TGO). Since BE Petrothai Group replacing fuel vehicles with EV cars started on August 1, 2022.

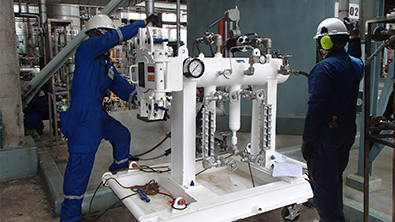

Provide and install an efficient ignite system called ‘Auto-Manual Flame Front Generator for Low Pressure Flare (AMFFG Ignition Panel for LP)’. This system will increase the reliability and safety of the equipment that causes flares in the Olefins Plant, Rayong.

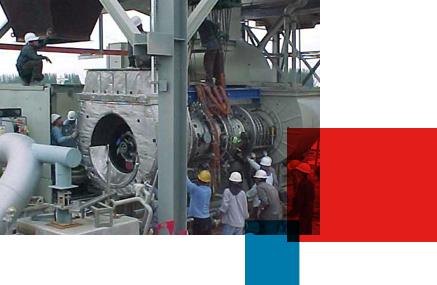

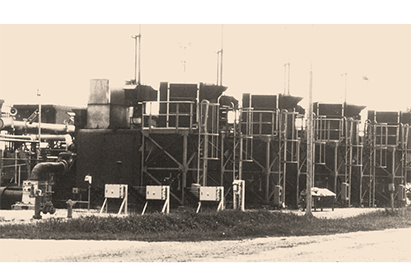

This new Gas Turbine model is designed to increase gas transmission force stability and a longer run length from 20,000 hours to 50,000 hours—the exchange is at the Gas Compression Station, Kanchanaburi.

Carbon Neutrality & Net Zero-emission technology are significant trends in Petroleum and Petrochemical industry.With collaboration from world-class manufacturers, KOCH Engineering Solution, Baker Hughes, Parker Haffins, Schmidt & Clemens, BE Petrothai Group held the 1st Live webinar 2021 on ‘Net Zero Emission Technology by Adaptive Innovation Partner’. Nearly 400 people from major petroleum and petrochemical companies participated.

During New Normal Situation, BE Petrothai Group utilize our local strength and collaborate online with global partners. We successfully installed VOC Elimination System for Environmental Improvement at Refinery plant, Rayong

Providing skid & on-site service for quality assurance at Gas Separation Plant, Rayong

Assemble 520, 451 EA in Valve tray

For Tower at Aromatic Plant, Rayong

Five companies under BE Petrothai Group have been certified all at once by Thai CAC (Thai Private Sector Collective Action Against Corruption).

Succeed with Partner, Marubeni-Itochu Steel Inc. to supply coated pipe 42” diameter, over than 400 kilometers in the 5th Transmission Pipeline Project, as main natural gas pipeline serving the country.

Reached an agreement with PTT to maintain Gas Compressor and Turbine in Kanchanaburi.

Supported our partner, GE Oil & Gas with strong local capability, to win supplying Gas Turbine driven Gas Compressors into the Midline Compressor Station to boost the gas of Thailand, in the 4th transmission pipeline.

Formation of 5 years framework agreement with PTTGC. To use special material for radiant coil (HTE) in the olefins plants to double lifespan from 4 to 7 years.

Facilitated customers conducted urgent 114-tonnes radiant coil delivery by air freight management from the German manufacturer to Rayong plant within 5 days.

Joined “Business Compliance Program” with a world-class partner, Marubeni Itochu Steel.

Distributed and imported liquid thermal oxidizer, LTO Plant a USA initiation technology, to assemble in Thailand and installed at gas separation plant (GSP) in Rayong by utilizing our specialization in engineering and project management.

inCyam Co. Ltd., an in-group of BE Petrothai Group, a business of distribution and import oil and gas and petrochemical industry machines, has been certified by Trace International organization of being an international anti-bribery standard and transparency in international commercial transactions.

Continually developed a series of “boonma” software to improve and add the feature of inventory management system e.g., control valve, spare part, and other equipment selection. Consequently, making customers use machines with full capacities and save cost.

Supplied considerable equipment, i.e., control valves, filters, and flare, to Ethane Separation Plant and the 6th Gas Separation Plant and succeed with partner.

Partnered up successfully and supplied major equipment into the country 3rd Transmission Gas Pipeline, for example, ball valves and filters.

OCTG Long term Contract, PTTEP & MITA to support PTTEP development plan for 5 consecutive years. Resulting in, adequate supplies of high-quality OCTG, 13% cr, and reduce inventory management cost during high demand for steel from all around the world.

Serviced PTT to relocate Gas Compressor from Chonburi to Ratchaburi. With the expertise of engineering and route management, the company helped PTT and the country save cost and extend machines activation.

During the critical Gas Compressor issue, Petrothai Corporation Ltd. liaised with 5 partners networking and fully committed to solving the problems at NPC in Rayong. The problem was solved 10 days faster than evaluation.

From database collection to knowledge formation, the company, first developed “boonma” software: Plant Maintenance Knowledge Management to operate and maintain machines efficiently for customers.

Petrothai Corporation Ltd. started re-engineering the company’s management system with BE Consulting Group (1987), the expertise of resource management and accounting consultant, then established BE Petrothai Group.

Import extensive range of equipment such as gas compressors, pumps, and valves in the 2nd wave of Thailand Petrochemical Development for TOC, ATC, RRC, SPRC.

Petrothai Corporation Ltd. signed a contract as a service provider of installing and setting Reciprocating Gas Compressor, which driven by the Gas Engine, from Thai Shell Exploration & Production Co., Ltd. in Sirikit Field, Kamphaeng Phet.

The company was a responsible for the sale of Centrifugal Gas Compressor, driven by Gas Turbine Aero-derivative type which is the significant machine to transmit natural gas from an onshore pipeline in Thailand “Onshore Compression Station #1” and the success committed to Onshore Compression Station #2 in 2001.